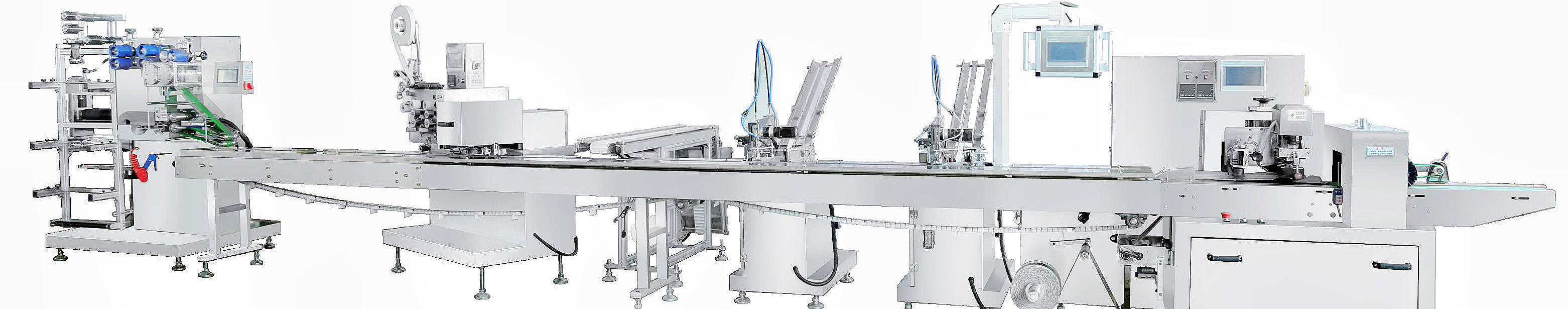

Simple, Efficient Packing Machines to Meet Your Needs

Let us help you overcome your toughest packaging automation challenges with intuitive, easy-to-use equipment.Whether your packaging needs are leading edge or more traditional, Zhengzhou Yashicun has a solution. Are you looking to improve ROI in your production and packaging processes? We can show you how with automation. And if you’re simply upgrading existing machines or know exactly what you want, our superior quality equipment provides a powerful solution that can be adapted to meet your needs.

Flexible packaging offers many benefits over its rigid counterpart, including a decreased carbon footprint, savings on shipping and storage, and a more prominent shelf-presence and a larger canvas for marketing. Applicable to almost every industry, both food and non-food, flexible packing machines increase both efficiency and your bottom line.

Interested in purchasing your first machine?

Cost-Effective Vertical Packing Machine

Technical Parameters

Measuring Scope: 0.1 – 1 kg

Bag...

View Details >

Cost-Effective Vertical Packing Machine

Technical Parameters

Measuring Scope: 0.1 – 1 kg

Bag...

View Details >

Automatic Pouch Packing Machine for Palm Oil

The YASHICUN Rotary Premade Pouch Packing Machine is a fully automatic solution for...

View Details >

Automatic Pouch Packing Machine for Palm Oil

The YASHICUN Rotary Premade Pouch Packing Machine is a fully automatic solution for...

View Details >

Food-Grade Stainless Steel Stick Pack Machine for...

This automatic stick pack machine is specifically engineered for high-viscosity pet food pastes,...

View Details >

Food-Grade Stainless Steel Stick Pack Machine for...

This automatic stick pack machine is specifically engineered for high-viscosity pet food pastes,...

View Details >

Nitrogen Flushed Premade Pouch Packaging Machine...

Key Advantages

Full-Cam Mechanical Design

No chains or cylinders; low...

View Details >

Nitrogen Flushed Premade Pouch Packaging Machine...

Key Advantages

Full-Cam Mechanical Design

No chains or cylinders; low...

View Details >

Retort Pouch Filling Machine for Cat Wet Food –...

Parameter

...

View Details >

Retort Pouch Filling Machine for Cat Wet Food –...

Parameter

...

View Details >

Automatic Pouch Inserting Machine for Cat Wet Food...

No.

Item

...

View Details >

Automatic Pouch Inserting Machine for Cat Wet Food...

No.

Item

...

View Details >

Automatic Rotary Premade Bag Packaging Machine

YASHICUN-8S-260 Automatic Rotary Premade pouch Machine

1. The YASHICUN-8S-260 standard model...

View Details >

Automatic Rotary Premade Bag Packaging Machine

YASHICUN-8S-260 Automatic Rotary Premade pouch Machine

1. The YASHICUN-8S-260 standard model...

View Details >

Zipper Pouch Packing Machine

8 stations, single bag

PLC control with touch screen operation...

View Details >

Zipper Pouch Packing Machine

8 stations, single bag

PLC control with touch screen operation...

View Details >

Stand Up Pouch Filling Packing Machine

- 8 stations

- Siemens 10 inch touch screen

- Pure Cam Drive System for...

View Details >

Stand Up Pouch Filling Packing Machine

- 8 stations

- Siemens 10 inch touch screen

- Pure Cam Drive System for...

View Details >