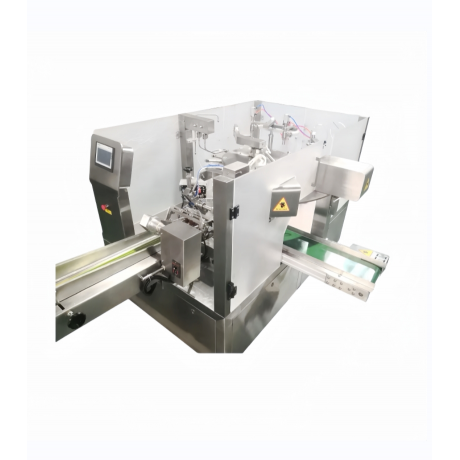

Zipper Pouch Packing Machine

Explore our Zipper Pouch Packing Machine, ideal for premade pouch packaging. This efficient, user-friendly machine ensures precision and durability. It offers customizable features to enhance your packaging process with our reliable solution.

Specification

8 stations, single bag

PLC control with touch screen operation (Siemens)

CAM-driven control platform

Highly durable welded steel frame

Waterproof system makes cleaning more convenient

Pouch presence detection – no filling, no sealing

Bag deflation with wire guide or push bars

Automatic deoxidizer feeding station

Two step sealing process guarantees clean sealing

Cooling station for liquid products

Features

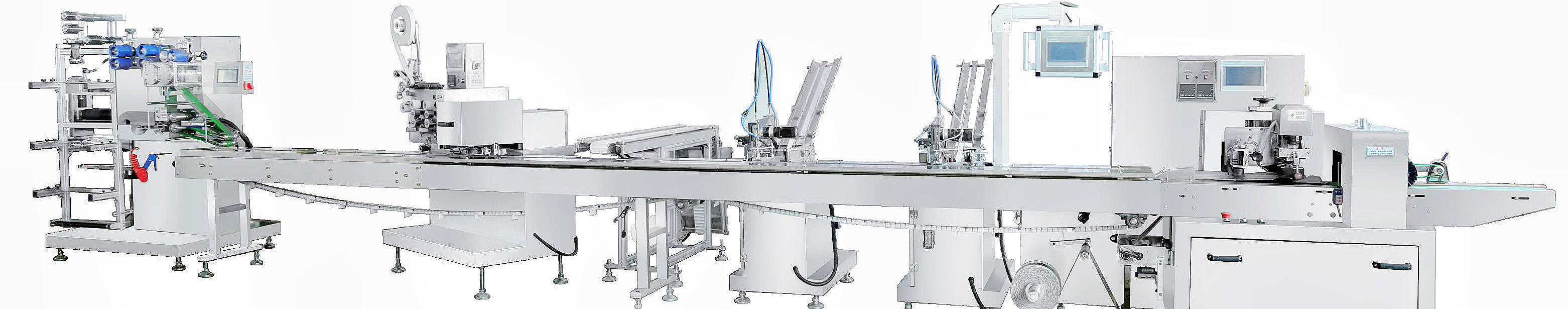

Our most popular simplex premade pouch filling and sealing machine for bags up to 245 mm wide at speeds up to 50 cycles per minute. The machine is also suitable for pre made zipper pouch applications, ensuring secure and efficient packaging.

|

Model |

4S-250 | 6S-200 | 8S-200A | 8S-250 | 8S-260 | 8S-300 | 10S-160 |

| Number of stations | 4 | 6 | 8 | 8 | 8 | 8 | 10 |

|

Number of Lanes |

1 | 1 | 1 | 1 | 1 | 1 | 1 |

|

Maximum Speed Per Minute (dry cycle) |

25 | 50 | 35 | 50 | 50 | 40 | 50 |

|

Bag Gripping Range (mm) |

90-250mm |

70-200mm |

100-200mm | 90-235mm | 100-245 | 200-300 | 90-150mm |

|

Maximum Bag Length (mm) |

300mm |

300mm(350mm

with extender)

|

300mm(350mm

with extender)

|

380mm(420mm

with extender)

|

380mm(420mm

with extender)

|

430mm |

300mm |

|

Power Supply |

4.5kw (38oV,three-phase,60Hz.,)

|

4.5kw (38oV,three-phase,60Hz.,) |

4,5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

|

Compressed Air |

Approx. 400NL/min, 3~4kgf/cm2 |

Approx.500NL/min,4-5kgf/cm |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

This table provides a clear specification of the main technical parameters, including speed, bag size, and weight capacity in kg.

Options:

- Proprietary Yashicun robotic pick & place bag infeed system

- Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

- Long raised rotary shaft extender for longer bags

- Extended bag magazine

- Date coding: emboss, hot stamp, inkjet or thermal transfer

- Quality control: checkweigher, metal detector, X-ray inspection

- Dust suction nozzles and dust collector

- Product settler

- Bag supporter for heavy fills

- Gas flush

- Bag rejection system

- Stand-up discharge

- Compatible with a wide range of film types, including heat-sealable flexible laminates and films for pouch sealing

The machine can be customized according to client specifications to meet specific production requirements and industry standards.

Electrical Configuration:

| Main Conponents | Supplier |

| PLC | Siemens |

| Touch Screen |

Siemens |

| Inverter | Schneider |

| Vacuum generator | SMC Japan |

| Photocell Autonics Korea | BANNER |

| Main Motor |

Siemens |

| Pneumatic Parts |

SMC Japan |

|

The electromagnetic valve |

SMC Japan |

In the dynamic world of packaging, innovation plays a crucial role in meeting the diverse needs of consumers and businesses alike. One such innovation is the Zipper Pouch Packing Machine, which has become an essential tool in the packaging industry. This article delves into the features, benefits, and applications of zipper pouch packing machines, highlighting why they are indispensable in today’s market.

What is a Zipper Pouch Packing Machine?

A Zipper Pouch Packing Machine is a specialized piece of equipment designed to fill and seal pre-made pouches with a zipper closure. Developed with advanced technology, these machines provide efficient pouch packaging solutions for a wide range of products. They are widely used in various industries, including food, beverages, cosmetics, and pharmaceuticals, to package products efficiently and securely.

Zipper Pouch Packing Machine Key Features and Benefits

Design: The thoughtful design of these machines, including modular and compact structures, enhances efficiency, ease of use, and adaptability to different customer requirements.

Automation: Zipper pouch packing machines are highly automated, reducing the need for manual labor and increasing production efficiency. They can handle multiple processes, including filling, sealing, and labeling, in a single operation.

Precision and Regulation: These machines offer precise control over the filling process, ensuring consistent product quality and minimizing waste. Advanced sensors and control systems help maintain accuracy and reliability, and the machine can regulate process parameters such as temperature and speed for optimal performance.

Versatility: Zipper pouch packing machines can accommodate a wide range of pouch sizes and shapes, making them suitable for various products. Whether it’s liquid, powder, or solid items, these machines can handle it all.

Sealing Technology: The sealing mechanism of zipper pouch packing machines ensures a strong and secure seal, enhancing the shelf life of the packaged product. Some machines also offer additional features like nitrogen flushing to further extend product freshness.

User-Friendly Interface: Modern zipper pouch packing machines come with intuitive user interfaces, making them easy to operate and program. This feature reduces the learning curve for operators and increases overall efficiency.

Compliance and Safety: These machines are designed to meet strict industry standards and regulations, ensuring the safety and compliance of the packaged products. They often come with features like automatic cleaning and sterilization to maintain hygiene.

Service: Comprehensive after-sales service and technical support are provided to ensure optimal machine operation and customer satisfaction.

Zipper Pouch Packing Machine Applications

Zipper pouch packing machines find applications in various industries due to their versatility and efficiency. Some common applications include:

Food Industry: Packaging snacks, cereals, coffee, tea, spices, and other food items in convenient and resealable pouches. The machine is highly suitable for packaging spices, ensuring freshness and aroma retention.

Beverage Industry: Filling and sealing pouches with juices, smoothies, and other beverages.

Cosmetics Industry: Packaging lotions, creams, paste products, and other beauty products in portable and easy-to-use pouches. The machine is capable of handling paste products such as tomato paste and sauces, with technical specifications tailored for viscous substances.

Pharmaceutical Industry: Ensuring the safe and secure packaging of medications and health supplements.

Hardware Industry: Efficiently packaging small hardware items such as nuts, washers, screws, and bolts, providing precise handling and alignment for manufacturing and assembly processes.

A wide range of machines is available in our store for immediate delivery, including automatic collar machines and related equipment.

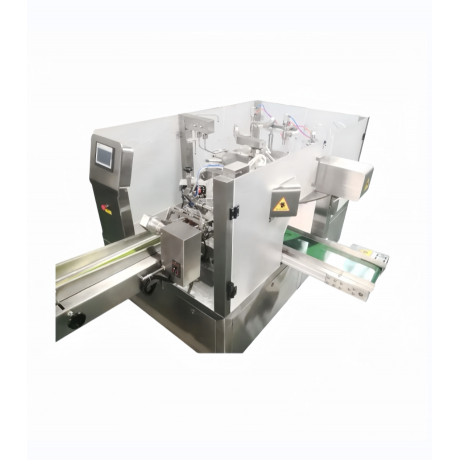

Zipper Pouch Packing Machine Components

The Zipper Pouch Packing Machine is engineered with a range of advanced components that work together to deliver efficient, high-accuracy packaging. At the heart of the machine is the zip insertion system, which automatically positions and secures the zipper tape into each pouch, ensuring a reliable zip open and close function for the end user. The sealing mechanism, featuring silicon rollers, applies precise pressure to achieve perfect sealing, preserving product freshness and preventing leaks.A customizable filling system allows for accurate dosing of products, whether you’re packaging powders, liquids, or solids. The PID temperature controller maintains optimal heat levels for consistent sealing, while the VFD drive regulates the machine’s speed to match your production requirements. Each component is designed to ensure smooth operation, high speed, and minimal waste, making the pouch packing machine a good choice for businesses seeking to enhance their packaging process. Understanding these components is key to maximizing the performance and longevity of your zipper pouch packing machine.

How to Operate a Zipper Pouch Packing Machine

Operating a Zipper Pouch Packing Machine is straightforward, thanks to its intuitive man machine interface. Begin by ensuring the machine is correctly assembled and all safety checks are complete. Load your pre-made zipper pouches into the designated magazine, then set your desired filling volume and packing speed using the user-friendly control panel. The interface allows for easy adjustments to accommodate different products and pouch sizes.Once the machine is started, it will automatically handle zip insertion, filling, and sealing, streamlining the entire pouch packing process. Regularly monitor the output and make any necessary adjustments to maintain consistent quality. By following the manufacturer’s guidelines and keeping an eye on the machine’s performance, you can ensure efficient, high-speed packaging and reliable results for every batch of zipper pouches.

Maintenance and Upkeep for Longevity

To keep your Zipper Pouch Packing Machine running at peak performance, regular maintenance is essential. Daily cleaning and lubrication of moving parts help prevent wear and tear, while periodic inspections ensure that critical components like the PID temperature controller, VFD drive, and silicon rollers are functioning correctly. Pay special attention to the zipper tape path and the pressure applied by the silicon rollers, as these are crucial for achieving perfect sealing and smooth zip insertion.Replace any worn or damaged parts promptly to avoid unexpected downtime and maintain high productivity. Proper storage and handling of the machine, along with adherence to the recommended maintenance schedule, will help your business get the most out of its investment. By prioritizing upkeep, you ensure that your pouch packing machine delivers reliable, high-quality packaging for years to come.

Customization Options for Your Packaging Needs

Every business has unique packaging requirements, and the Zipper Pouch Packing Machine is designed with flexibility in mind. Depending on your product—be it food, pharmaceuticals, or cosmetics—the machine can be equipped with different types of filling systems, such as volumetric, auger, or multi-head weighers, to ensure accurate and efficient filling. The speed and output of the machine can be tailored to match your production process, whether you need high-speed runs or smaller, specialized batches.The machine’s construction and material can be customized to meet industry-specific standards, ensuring compatibility with your products and compliance with regulations. It can also be designed to handle a variety of pouch and bag types, including pre-made zipper pouches in different sizes and materials. By working closely with the manufacturer, businesses can develop a pouch packing machine that is perfectly suited to their packaging needs, maximizing efficiency and product quality.

Machine Safety: Protecting Your Team and Product

Safety is a top priority in any packaging process, and the Zipper Pouch Packing Machine is equipped with robust features to protect both operators and products. Safety guards and interlocks are integrated into the machine’s construction to prevent accidental contact with moving parts during operation. The close function and contact parts are designed for easy inspection and maintenance, reducing the risk of injury and ensuring hygienic packaging conditions.Operators should always follow established safety protocols, including wearing appropriate protective gear and participating in regular training sessions. Routine inspections of the zip insertion and zip open systems help prevent malfunctions and maintain consistent product quality. By adhering to international safety standards and maintaining the machine’s features, businesses can ensure a safe working environment and reliable packaging results, meeting both regulatory requirements and customer expectations.

Leading Zipper Pouch Packing Machine Manufacturer from China

When it comes to choosing a reliable zipper pouch packing machine, it’s essential to consider manufacturers known for their quality and innovation. One such leading manufacturer in China is YSC Packaging Machine. YSC is renowned for its advanced technology, robust build, and customer-centric approach. They offer competitive price options to ensure affordability for businesses of all sizes. Their machines are designed to meet the highest standards of performance and reliability, making them a preferred choice for businesses worldwide. By improving efficiency and automation, YSC machines can help boost customer sales and production capacity.orldwide.

Conclusion

The Zipper Pouch Packing Machine has transformed the packaging landscape, offering unparalleled efficiency, precision, and versatility. Its ability to handle a wide range of products and provide secure, resealable packaging makes it an invaluable asset for businesses across various industries. By investing in a high-quality zipper pouch packing machine from a reputable manufacturer like YSC Packaging Machine, companies can enhance their production capabilities and meet the evolving demands of the market.

Whether you're in the food, beverage, cosmetic, or pharmaceutical industry, a zipper pouch packing machine is a smart investment that can streamline your packaging process and improve your bottom line.