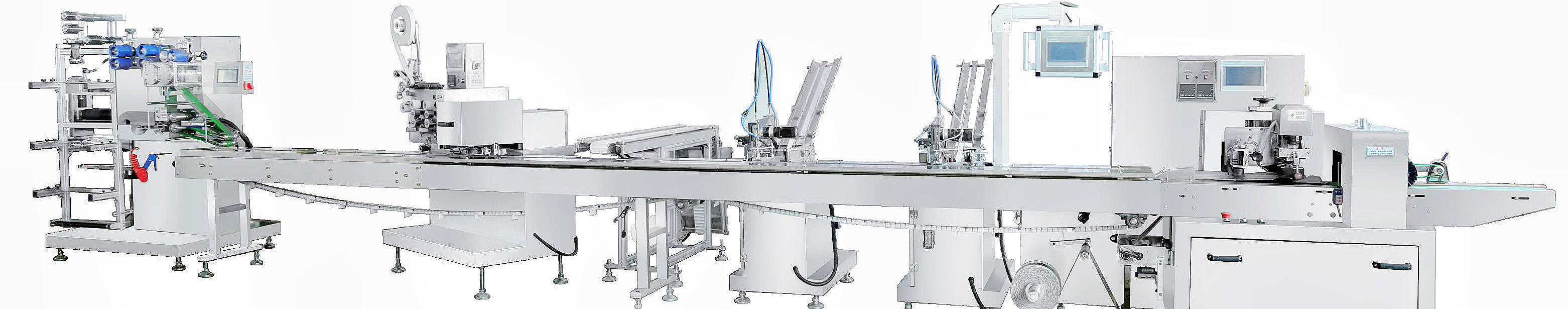

Retort Pouch Filling Machine for Cat Wet Food – Model YASHICUN-200

This automatic pouch filling machine is specially designed for:

-

Cat wet food with sauce or gravy

-

Tuna or shredded chicken-based pet meals

-

Small-volume ready-to-eat pet food packed in retort pouches

Specification

| Parameter | Specification |

|---|---|

| Model | YASHICUN-200 |

| Pouch Type | Premade single retort pouch |

| Bag Size Range | Width: 70–190 mm, Length: 100–350 mm |

| Filling Range | 30–150 ml |

| Filling Accuracy | ±1% |

| Number of Stations | 8 |

| Pouch Gripping Force | ≤1.5 kg |

| Packaging Speed | Up to 50 bags/min |

| Main Construction Material | Stainless Steel 304 |

Main Components

Component

Brand / Origin

PLC & Touch Screen

Siemens (Germany)

Inverter

Schneider (France)

Main Motor

Siemens (Germany)

Pneumatic Parts & Valves

Airtac &

Vacuum pump

Orion (Japan)

Features

The YASHICUN-200 is a high-performance retort pouch filling machine specifically designed for packing wet cat food into single-serve premade pouches, particularly ideal for 55g gravy-based recipes. With precise filling control, stable output, and hygienic design, it is the preferred solution for modern pet food production lines.

Product Highlights

-

High-speed pouch packing with a maximum capacity of 50 bags per minute, and filling speed up to 65 bags per minute (30–150ml range).

-

Equipped with a 10-inch Siemens touch screen and Siemens PLC, ensuring stable operation and intuitive user control.

-

8 working stations to complete the full cycle from pouch feeding to cold sealing.

-

Advanced cam-driven control system for long-lasting mechanical accuracy and reliability.

-

Bag presence detection system automatically prevents filling or sealing if no pouch is detected, reducing waste and preventing mess.

-

Integrated deoxidizer feeding station extends product shelf life by reducing oxygen in the pouch.

-

Dual sealing system with heat sealing followed by cold sealing, ideal for liquid and gravy-rich pet food.

-

Water channel body structure made from 304 stainless steel, easy to clean and corrosion-resistant.

-

Bag deflation handled by guide wire or push bar before sealing to eliminate internal air pockets.

Work Process

-

Bag Feeding – Automatically picks and positions premade pouches.

-

Coding and Date Printing – Applies production or expiration dates via thermal printer.

-

Pouch Opening – Opens the pouch mouth using vacuum and air-blowing mechanisms.

-

Product Filling – Accurately fills wet cat food into the pouch.

-

Cleaning the Bag Mouth – Removes residue to ensure clean sealing surfaces.

-

Heat Sealing (Grain Texture) – First heat seal using textured sealing jaws.

-

Heat Sealing (Flat Texture) – Second heat seal using smooth sealing jaws for strength and appearance.

-

Cold Sealing – Final cooling process to stabilize the seal, especially important for liquid or retort products.