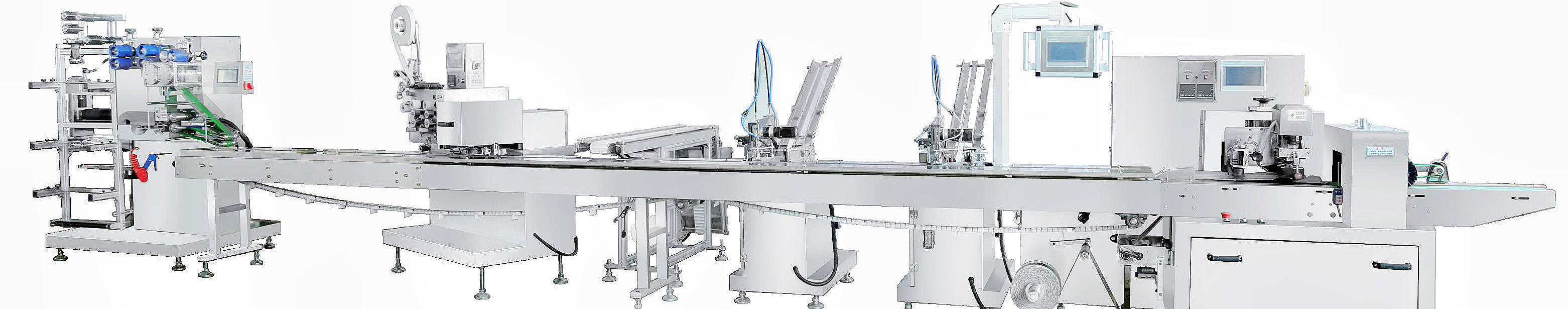

Pouch Fill and Seal Machine

Rotary pouch filler and sealer is ideal for packaging powders and food products.

Specification

8 stations, single bag

PLC control with touch screen operation

CAM-driven control platform

Highly durable welded steel frame

Waterproof system makes cleaning more convenient

Pouch presence detection – no filling, no sealing

Bag deflation with wire guide or push bars

Automatic deoxidizer feeding station

Two step sealing process guarantees clean sealing

Cooling station for liquid products

Features

Our most popular simplex premade pouch fill and seal machine for bags up to 245 mm wide at speeds up to 50. cycles per minute

|

Model |

4S-250 | 6S-200 | 8S-200A | 8S-250 | 8S-260 | 8S-300 | 10S-160 |

| Number of stations | 4 | 6 | 8 | 8 | 8 | 8 | 10 |

|

Number of Lanes |

1 | 1 | 1 | 1 | 1 | 1 | 1 |

|

Maximum Speed Per Minute (dry cycle) |

25 | 50 | 35 | 50 | 50 | 40 | 50 |

|

Bag Gripping Range (mm) |

90-250mm |

70-200mm |

100-200mm | 90-235mm | 100-245 | 200-300 | 90-150mm |

|

Maximum Bag Length (mm) |

300mm |

300mm(350mm with extender) |

300mm(350mm with extender) |

380mm(420mm with extender) |

380mm(420mm with extender) |

430mm |

300mm |

|

Power Supply |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4,5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

|

Compressed Air |

Approx. 400NL/min, 3~4kgf/cm2 |

Approx.500NL/min,4-5kgf/cm |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Options:

Proprietary Yashicun robotic pick & place bag infeed system

Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

Long raised rotary shaft extender for longer bags

Extended bag magazine

Date coding: emboss, hot stamp, inkjet or thermal transfer

Quality control: checkweigher, metal detector, X-ray inspection

Dust suction nozzles and dust collector

Product settler

Bag supporter for heavy fills

Gas flush

Bag rejection system

Stand-up discharge

Electrical Configuration:

| Main Conponents | Supplier |

| PLC | Siemens |

| Touch Screen |

Siemens |

| Inverter | Schneider |

| Vacuum generator | SMC Japan |

| Photocell Autonics Korea | BANNER |

| Main Motor |

Siemens |

| Pneumatic Parts |

SMC Japan |

|

The electromagnetic valve |

SMC Japan |

What is a Pouch Fill and Seal Machine?

A Pouch Fill and Seal Machine is a specialized device used to fill pre-formed pouches with various products, such as liquids, powders, granules, or solid items, and then seal the pouches to ensure product integrity and safety. These machines are widely employed in industries ranging from food and beverages to pharmaceuticals, cosmetics, and chemicals. By automating the filling and sealing processes, pouch fill and seal machines enhance efficiency, reduce labor costs, and improve product quality.Pouch Fill and Seal Machine Key Features and Benefits

1. High Efficiency and Productivity- Pouch fill and seal machines are designed to operate at high speeds, significantly reducing the time required to package products. This increased efficiency translates to higher productivity and throughput, allowing businesses to meet growing demand and expand their market reach.

2. Precision and Consistency

- These machines offer precise control over the filling process, ensuring consistent product weights and volumes. This precision helps minimize waste, reduce product giveaway, and maintain product quality, which is essential for customer satisfaction and brand reputation.

3. Versatility

- Pouch fill and seal machines are highly versatile and can accommodate a wide range of pouch sizes and materials. Whether you need to package small single-serving portions or larger quantities, these machines can be easily adjusted to suit your specific needs. Additionally, they can handle various product types, from liquids and pastes to powders and solids.

4. Enhanced Safety and Hygiene

- The automated nature of pouch fill and seal machines reduces the risk of contamination and ensures a hygienic packaging environment. This is particularly important in industries such as food and pharmaceuticals, where product safety is paramount. Many machines also feature advanced cleaning and sterilization systems to further enhance hygiene standards.

5. Cost-Effectiveness

- By automating the packaging process, pouch fill and seal machines help reduce labor costs and minimize the need for manual intervention. The increased efficiency and reduced waste also contribute to lower overall production costs, making these machines a cost-effective investment for businesses of all sizes.

6. Customizable Options

- Pouch fill and seal machines often come with a variety of customization options to meet specific industry requirements. For example, some machines may include features such as nitrogen flushing to extend product shelf life, or vacuum sealing for enhanced preservation. Customizable options allow businesses to tailor the machine to their unique needs and optimize their packaging processes.

7. Ease of Use and Maintenance

- Modern pouch fill and seal machines are designed with user-friendly interfaces and intuitive controls, making them easy to operate and program. Many models also feature modular designs that simplify maintenance and repairs, reducing downtime and ensuring continuous operation.

8. Sustainability

- As environmental concerns become increasingly important, pouch fill and seal machines offer a sustainable packaging solution. By using pre-formed pouches, these machines generate less waste compared to traditional packaging methods. Additionally, many pouch materials are recyclable, further reducing the environmental impact of packaging operations.

9. Flexibility in Packaging Design

- Pouch fill and seal machines can accommodate a wide range of pouch designs, including stand-up pouches, gusseted pouches, and resealable pouches. This flexibility allows businesses to choose the most suitable packaging format for their products, enhancing consumer convenience and appeal.

10. Integration with Other Systems

- Pouch fill and seal machines can be easily integrated with other packaging and production systems, such as conveyors, labelers, and case packers. This integration enables seamless workflow management and enhances overall operational efficiency.

Applications of Pouch Fill and Seal Machines

Pouch fill and seal machines find applications in a diverse range of industries, including:- Food and Beverage: Packaging of snacks, coffee, tea, spices, sauces, and beverages.

- Pharmaceuticals: Packaging of powders, capsules, tablets, and liquid medications.

- Cosmetics and Personal Care: Packaging of creams, lotions, shampoos, and conditioners.

- Chemicals: Packaging of industrial chemicals, fertilizers, and pesticides.

- Pet Food: Packaging of dry and wet pet food products.

In each of these industries, pouch fill and seal machines play a vital role in ensuring product quality, safety, and consumer satisfaction.