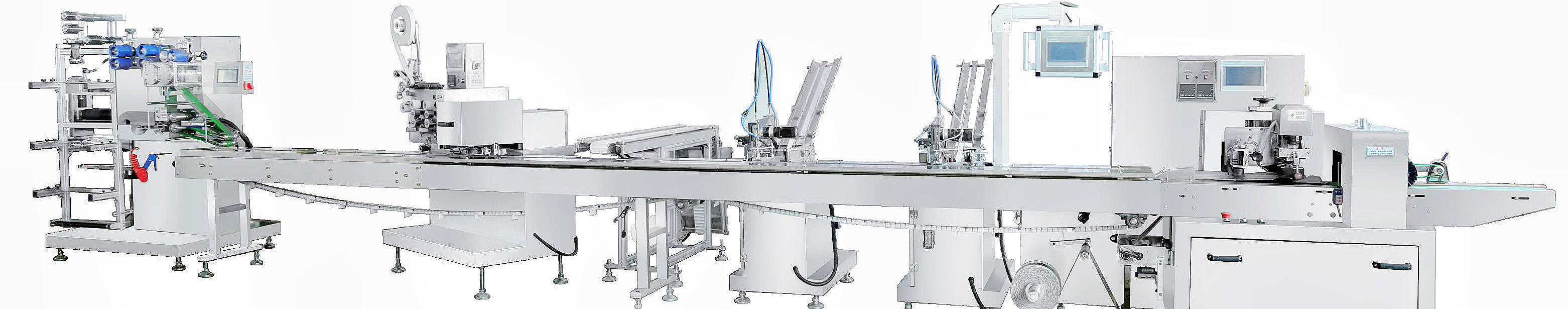

Rotary Premade Pouch Machine

Max Speed: 50 bags / min

Bag size:

Max. 245 x 320 mm

Min. 90 x 40 mm

Specification

8 stations, single bag

PLC control with touch screen operation

CAM-driven control platform

Highly durable welded steel frame

Waterproof system makes cleaning more convenient

Pouch presence detection – no filling, no sealing

Bag deflation with wire guide or push bars

Automatic deoxidizer feeding station

Two step sealing process guarantees clean sealing

Cooling station for liquid products

Features

Our most popular simplex premade pouch filling and sealing machine for bags up to 245 mm wide at speeds up to 50. cycles per minute

4.5kw

(38oV,three-phase,60Hz.,)

4,5kw

(38oV,three-phase,60Hz.,)

4.5kw

(38oV,three-phase,60Hz.,)

4.5kw

(38oV,three-phase,60Hz.,)

4.5kw

(38oV,three-phase,60Hz.,)

4.5kw

(38oV,three-phase,60Hz.,)

Approx. 400NL/min,

3~4kgf/cm2

Approx. 600NL/min,

5~6kgf/cm2

Approx. 600NL/min,

5~6kgf/cm2

Approx. 600NL/min,

5~6kgf/cm2

Approx. 600NL/min,

5~6kgf/cm2

Approx. 600NL/min,

5~6kgf/cm2

Model

4S-250

6S-200

8S-200A

8S-250

8S-260

8S-300

10S-160

Number of stations

4

6

8

8

8

8

10

Number of Lanes

1

1

1

1

1

1

1

Maximum Speed Per Minute (dry cycle)

25

50

35

50

50

40

50

Bag Gripping Range (mm)

90-250mm

70-200mm

100-200mm

90-235mm

100-245

200-300

90-150mm

Maximum Bag Length (mm)

300mm

300mm(350mm

with extender)

300mm(350mm

with extender)

380mm(420mm

with extender)

380mm(420mm

with extender)

430mm

300mm

Power Supply

4.5kw (38oV,three-phase,60Hz.,)

Compressed Air

Approx.500NL/min,4-5kgf/cm

Options:

Proprietary Yashicun robotic pick & place bag infeed system

Product filling – can be integrated with multi-head scales, volumetric fillers and auger fillers

Long raised rotary shaft extender for longer bags

Extended bag magazine

Date coding: emboss, hot stamp, inkjet or thermal transfer

Quality control: checkweigher, metal detector, X-ray inspection

Dust suction nozzles and dust collector

Product settler

Bag supporter for heavy fills

Gas flush

Bag rejection system

Stand-up discharge

Electrical Configuration:

Main Conponents

Supplier

PLC

Siemens

Touch Screen

Siemens

Inverter

Schneider

Vacuum generator

SMC Japan

Photocell Autonics Korea

BANNER

Main Motor

Siemens

Pneumatic Parts

SMC Japan

The electromagnetic valve

SMC Japan

In the modern world of packaging, efficiency and precision are paramount. One technology that stands out in this regard is the Premade Pouch Filling Machine. This innovative equipment has revolutionized the way liquids and other products are packaged, offering numerous advantages over traditional methods.

What is a Premade Pouch Filling Machine?

A Premade Pouch Filling Machine is a specialized piece of equipment designed to fill pre-made pouches with various products, such as olive oil, sunflower oil, beverages, and other commodities. These machines are highly versatile and can handle different types of pouches, including stand-up pouches and doypacks.

Key Features and Benefits of Premade Pouch Filling Machine

1. Automation: Premade pouch filling machines are fully automated, which significantly reduces the need for manual labor. This automation leads to increased productivity and consistency in the packaging process.

2. Precision: These machines are equipped with advanced weighing and filling systems that ensure precise dosing of the product. This precision helps minimize waste and ensures that each pouch contains the exact amount of product specified.

3. Versatility: Premade pouch filling machines can handle a wide range of products, from liquids to powders and granules. This versatility makes them suitable for various industries, including food and beverage, pharmaceuticals, and cosmetics.

4. Hygiene: The machines are designed to maintain high levels of hygiene, which is crucial in the food and pharmaceutical industries. Many models come with features such as easy-to-clean surfaces and stainless steel construction.

5. Cost-Effective: While the initial investment in a premade pouch filling machine may be significant, the long-term cost savings are substantial. The reduced labor costs, improved efficiency, and minimized waste all contribute to a lower overall cost of production.

6. Customization: Many manufacturers offer customization options to meet specific needs. This includes different filling speeds, pouch sizes, and additional features like labeling and sealing.

Applications of Premade Pouch Filling Machine

Premade pouch filling machines are used in a variety of industries, including:

- Food and Beverage: For packaging products like olive oil, sunflower oil, juices, and sauces.

- Pharmaceuticals: For packaging liquid medications, powders, and capsules.

- Cosmetics: For packaging lotions, creams, and other beauty products.

- Chemicals: For packaging household and industrial chemicals.

Maintenance and Support of Premade Pouch Filling Machine

To ensure optimal performance, regular maintenance of the premade pouch filling machine is essential. Most manufacturers offer comprehensive support services, including video tutorials, online support, and free spare parts. This support helps extend the lifespan of the machine and ensures minimal downtime.

Conclusion

The Premade Pouch Filling Machine is a vital piece of equipment in modern packaging operations. Its automation, precision, versatility, and cost-effectiveness make it an attractive option for businesses looking to improve their packaging processes. As technology continues to advance, these machines are likely to become even more efficient and capable, further solidifying their importance in the industry.

For businesses considering investing in a premade pouch filling machine, it is essential to choose a reputable manufacturer that offers high-quality equipment and excellent customer support. By doing so, they can ensure that they are making a wise investment that will benefit their operations for years to come.