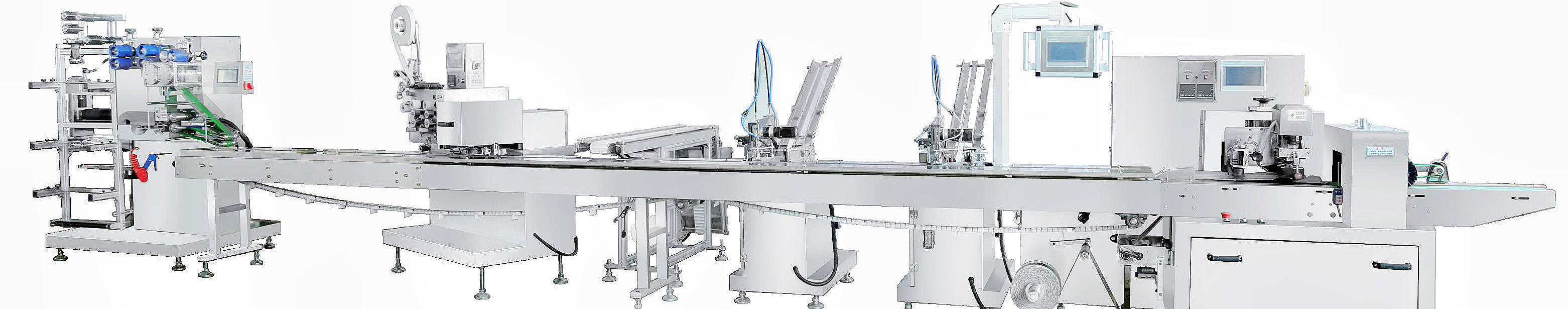

Automatic Rotary Premade Bag Packaging Machine

Max speed: 70 bags per minute

Can provide CE certification

Specification

YASHICUN-8S-260 Automatic Rotary Premade pouch Machine

1. The YASHICUN-8S-260 standard model weighs 1500kg, reflecting our high standards in utilizing stainless steel materials for both the machine frame and all workstations.

-At a high-speed operation of 70 bags per minute:

- The bag pickup column remains stable without vibration.

- The bag gripper securely holds 3-4kg of material.

- The bag detection device operates accurately along the work path.

- The heat sealing unit’s stability ensures neat and consistent sealing.

2. The machine features a cam-driven system with cams made from 20CrTi and 40Cr, offering high hardness, wear resistance, and impact resistance, making it ideal for high-speed, heavy-duty packaging line

3. The gear-to-gear mechanical transmission structure provides high precision, efficiency, and speed, making it suitable for heavy-duty operations with a long service life and no easily worn parts.

4. The independently developed indexing box ensures high indexing accuracy and excellent high-speed performance, enabling smooth operation, low noise, and a lifespan exceeding 5 years.

Features:

1. 8 stations, single bag operation

2. Siemens PLC and 10-inch Siemens touch screen

3. Cam-driven, gear-to-gear mechanism ensures high stability and efficiency

4. Highly durable welded 304 stainless steel frame

5. Automatic fault detection and alarm system

6. Pouch presence detection – no filling, no sealing

7. One-touch bag width adjustment8. Two-step sealing process guarantees clean sealing

Features

|

Model |

4S-250 | 6S-200 | 8S-200A | 8S-250 | 8S-260 | 8S-300 | 10S-160 |

| Number of stations | 4 | 6 | 8 | 8 | 8 | 8 | 10 |

|

Number of Lanes |

1 | 1 | 1 | 1 | 1 | 1 | 1 |

|

Maximum Speed Per Minute (dry cycle) |

25 | 50 | 35 | 50 | 50 | 40 | 50 |

|

Bag Gripping Range (mm) |

90-250mm |

70-200mm |

100-200mm | 90-235mm | 100-245 | 200-300 | 90-150mm |

|

Maximum Bag Length (mm) |

300mm |

300mm(350mm with extender) |

300mm(350mm with extender) |

380mm(420mm with extender) |

380mm(420mm with extender) |

430mm |

300mm |

|

Power Supply |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4,5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

4.5kw (38oV,three-phase,60Hz.,) |

|

Compressed Air |

Approx. 400NL/min, 3~4kgf/cm2 |

Approx.500NL/min,4-5kgf/cm |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Approx. 600NL/min, 5~6kgf/cm2 |

Options:

1. Product filling – compatible with multi-head scales, volumetric fillers, and auger fillers

2. Fully interlocked safety guards

3. Long raised rotary shaft extender for longer bags

4. Extended bag magazine

5. Date coding: emboss, hot stamp, inkjet, or thermal transfer

6. Quality control: checkweigher, metal detector, X-ray inspection

7. Dust suction nozzles and dust collector

8. Bag supporter for heavy fills

9. Ethernet connectivity

10. 99.99% purity nitrogen gas flush function

11. Exhaust system

Technical Specifications:

1. Net Weight of Standard Machine: 1458 kg

2. Number of Stations: 8

3. Maximum Speed Per Minute (dry cycle): 60-80 bags

4. Gripping Range (mm): 90-250mm

5. Maximum Gripping Force (kg): 4kg

6. Maximum Bag Length (mm): 420mm

7. Power Supply: 380 V / 3 Ph / 60 Hz (customizable)

8. Compressed Air: Approx. 700NL/min, 5-6kgf/cm²

9.Machine dimensions (LxWxH): 2000mm x 1600mm x 1600mm

Main Configuration:

1. PLC: Siemens (Germany)

2. Touchscreen: Siemens (Germany)

3. Inverter: Siemens (Germany)

4. Main Motor: Siemens (Germany)

5. Vacuum Pump: ORION (Japan)

6. Solenoid Valve: FESTO (Germany)

7. Composite Engineering Bearing: Igus (Germany)

In the dynamic world of packaging, innovation and efficiency are key drivers of success. One such innovation that has gained significant traction is the Preformed Bag Packaging Machine. This advanced machinery plays a crucial role in streamlining the packaging process, ensuring high productivity and superior product protection. In this article, we will delve into the intricacies of preformed bag packaging machines, exploring their features, benefits, and applications.

What is a Preformed Bag Packaging Machine?

A Preformed Bag Packaging Machine is a specialized piece of equipment designed to package products using pre-made bags. These bags are typically manufactured separately and are ready to be filled and sealed. The machine automates the process of inserting the product into the bag, sealing it, and preparing it for distribution. This technology is widely used across various industries, including food and beverage, pharmaceuticals, cosmetics, and more.Preformed Bag Packaging Machine Key Features and Benefits

1. Efficiency and Speed: Preformed bag packaging machines are engineered for high-speed operation, significantly reducing packaging time and increasing overall productivity. The automation of the filling and sealing processes ensures a seamless workflow, allowing businesses to meet high demand efficiently.2. Versatility: These machines are highly versatile and can accommodate a wide range of bag sizes and shapes. Whether it's small pouches for individual servings or large bags for bulk products, preformed bag packaging machines can handle it all. This adaptability makes them suitable for various packaging needs across different industries.

3. Product Protection: The use of preformed bags provides excellent protection for the packaged products. These bags are often made from high-quality materials that offer superior barrier properties, protecting the contents from external factors such as moisture, air, and contaminants. This ensures the freshness and integrity of the products during storage and transportation.

4. Cost-Effectiveness: Investing in a preformed bag packaging machine can lead to significant cost savings in the long run. The automated process reduces the need for manual labor, lowering operational costs. Additionally, the precise filling and sealing capabilities minimize product waste, further enhancing cost efficiency.

5. Ease of Use: Modern preformed bag packaging machines are designed with user-friendly interfaces and intuitive controls. This makes them easy to operate and maintain, even for personnel with minimal training. The simplicity of use ensures smooth operation and minimizes downtime.

6. Customization Options: Many preformed bag packaging machines offer customization options to meet specific packaging requirements. This includes adjustable settings for bag size, filling volume, and sealing parameters. Customizable features allow businesses to tailor the packaging process to their unique needs, ensuring optimal results.

7. Compliance with Regulations: The packaging industry is subject to stringent regulations and standards. Preformed bag packaging machines are designed to comply with these regulations, ensuring that the packaged products meet all necessary safety and quality criteria. This compliance helps businesses avoid legal issues and build consumer trust.

8. Environmental Sustainability: As environmental concerns become increasingly important, many preformed bag packaging machines are designed with sustainability in mind. They often use eco-friendly materials and energy-efficient technologies, reducing the environmental impact of the packaging process. This commitment to sustainability aligns with the growing demand for environmentally responsible practices.

9. Integration with Existing Systems: Preformed bag packaging machines can be easily integrated into existing packaging lines and systems. This seamless integration allows businesses to enhance their current operations without the need for extensive modifications or disruptions. The compatibility with other equipment ensures a cohesive and efficient packaging workflow.

10. Consistency and Quality: The automated nature of preformed bag packaging machines ensures consistent and high-quality packaging results. The precise control over the filling and sealing processes eliminates variations and inconsistencies, resulting in uniform and professional-looking packages. This consistency enhances brand image and customer satisfaction.

11. Flexibility in Product Types: Preformed bag packaging machines can handle a diverse range of product types, from dry goods and powders to liquids and semi-solids. This flexibility makes them suitable for various applications, including food packaging, pharmaceuticals, personal care products, and more. The ability to package different product types adds value and versatility to the packaging process.

12. Scalability: Whether a business is small or large, preformed bag packaging machines offer scalable solutions to meet varying production volumes. They can be configured to accommodate different output levels, making them suitable for both small-scale operations and high-volume production runs. This scalability ensures that businesses can adapt to changing demands and expand their operations as needed.

13. Enhanced Safety: The use of preformed bags and automated packaging processes reduces the risk of contamination and product tampering. The sealed environment provided by the machine ensures that the products remain safe and secure throughout the packaging process. This enhanced safety is particularly important in industries such as food and pharmaceuticals, where product safety is a top priority.

14. Data Management and Traceability: Advanced preformed bag packaging machines often come equipped with data management systems that track and record various aspects of the packaging process. This includes information on batch numbers, production dates, and quality control data. The ability to manage and trace this data enhances transparency and accountability, facilitating better inventory management and quality assurance.

15. Reduced Downtime: The robust design and reliable performance of preformed bag packaging machines minimize the risk of breakdowns and downtime. Regular maintenance and the use of high-quality components ensure that the machines operate smoothly and consistently. Reduced downtime translates to increased productivity and lower operational costs.

16. Innovation and Technological Advancements: The packaging industry is constantly evolving, and preformed bag packaging machines are at the forefront of technological advancements. Innovations such as smart sensors, artificial intelligence, and IoT integration are being incorporated into these machines to enhance their functionality and performance. These technological advancements enable businesses to stay ahead of the curve and leverage cutting-edge solutions for their packaging needs.

17. Customer Satisfaction: High-quality packaging not only protects products but also enhances the overall customer experience. Preformed bag packaging machines ensure that products are presented in a professional and appealing manner, which can positively impact customer perceptions and satisfaction. Satisfied customers are more likely to make repeat purchases and recommend the brand to others, contributing to long-term business success.

18. Global Market Reach: Preformed bag packaging machines are widely used in various regions around the world, catering to the global demand for efficient and reliable packaging solutions. Leading manufacturers in countries like China, such as YSC Packaging Machine, are known for producing high-quality preformed bag packaging machines that meet international standards. These machines are exported to different parts of the world, helping businesses expand their market reach and tap into new opportunities.

19. Training and Support: Reputable manufacturers of preformed bag packaging machines, like YSC Packaging Machine, provide comprehensive training and support services to their clients. This includes operator training, technical assistance, and after-sales support. The availability of training and support ensures that businesses can maximize the benefits of their investment and achieve optimal performance from their packaging machines.

20. Future-Proof Solutions: Investing in a preformed bag packaging machine is a future-proof decision. These machines are designed to adapt to changing market trends and technological advancements. Their modular design and upgradable features allow businesses to easily incorporate new functionalities and improvements as they become available. This future-proof approach ensures that businesses remain competitive and relevant in the ever-evolving packaging industry.