RFQ for premade pouch machine

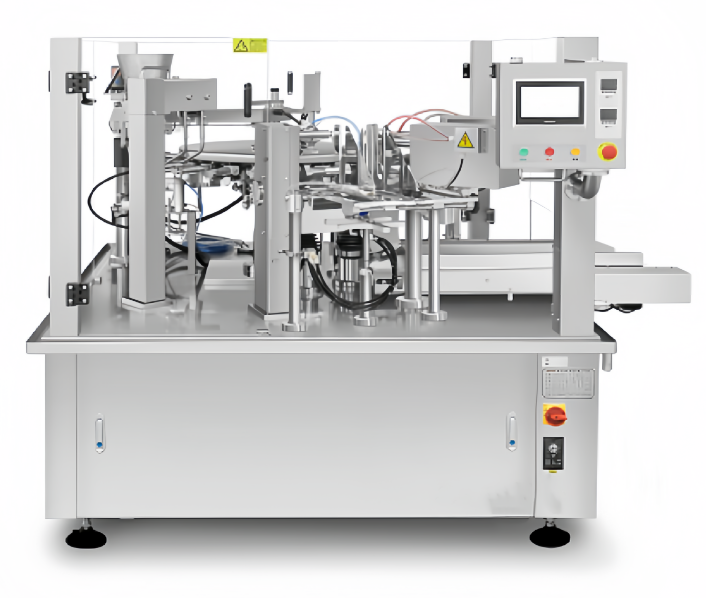

As a packaging machine factory based in China, achieving optimal performance and efficiency in your premade pouch machines is crucial for maintaining competitiveness in the global market. In this article, we will delve into key aspects of premade pouch machines, focusing on sealing effectiveness, zipper placement, and the workings of the YSC-8S-200 and 10-station models.

Achieving the Best Sealing Effect

Sealing quality is paramount in packaging. Here are some tips to ensure the best sealing effect:

-

Select the Right Sealing Temperatures and Pressures: The choice of sealing temperature and pressure depends on the packaging material and its thickness. Finding the optimal balance is crucial for a strong seal.

-

Keep the Sealing Area Clean: Any foreign substances in the sealing area can compromise seal quality. Ensure this area is free from contaminants like powder or liquids.

-

Adjust the Fill Volume Appropriately: The distance between the top layer of the product and the sealing area should be one-third of the total length of the bag to allow for an effective seal.

-

Regularly Check and Maintain the Sealing Machine: Inspect the heating elements and pressure settings regularly and make necessary adjustments to maintain optimal performance.

-

Conduct Sample Tests: Before mass production, conduct sample tests to ensure the sealing meets expected standards. Adjust parameters if necessary.

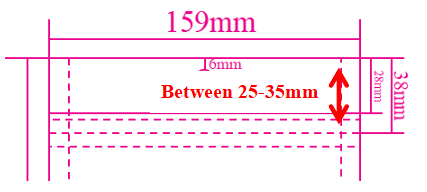

Zipper Placement for Easy Opening and Closing

The placement of the zipper is crucial for user convenience. A distance of 25-35mm from the top of the bag mouth is recommended to facilitate easy opening and closing by the machine.

Working Process of the YSC-8S-200 Premade Pouch Machine

The YSC-8S-200 model follows a systematic process:

- Bag Loading

- Coding

- (Reserve) Open the Zipper

- Open the Bag

- Filling & Vibrating (Oxygen absorbers can be added if required)

- Reserve (Nitrogen Flushing)

- First Heat Seal

- Second Heat Seal or Cool Seal

10-Station Premade Pouch Machines

For businesses requiring higher efficiency, 10-station premade pouch machines like the YSC-10S-160 and YSC-10S-220 models are available. These machines follow a similar process with additional stations for added functionality such as adding oxygen absorbers, nitrogen flushing, and extra sealing steps.

In conclusion, optimizing the performance of your premade pouch machines involves careful attention to sealing parameters, zipper placement, and regular maintenance. By adhering to these guidelines, you can ensure the reliability and efficiency of your packaging operations, positioning your factory as a leader in the global packaging machine market.