Zipper Pouch Packing Machine: Revolutionizing the Packaging Industry

In today’s fast-paced world, packaging plays a crucial role in product preservation, convenience, and appeal. Among the many packaging solutions available, zipper pouch packaging has gained widespread popularity due to its convenience, functionality, and ability to preserve products for longer periods. A zipper pouch packing machine is at the forefront of this revolution, allowing manufacturers to automate the process of sealing products in pouches that are both secure and easy to use.

In today’s fast-paced world, packaging plays a crucial role in product preservation, convenience, and appeal. Among the many packaging solutions available, zipper pouch packaging has gained widespread popularity due to its convenience, functionality, and ability to preserve products for longer periods. A zipper pouch packing machine is at the forefront of this revolution, allowing manufacturers to automate the process of sealing products in pouches that are both secure and easy to use.

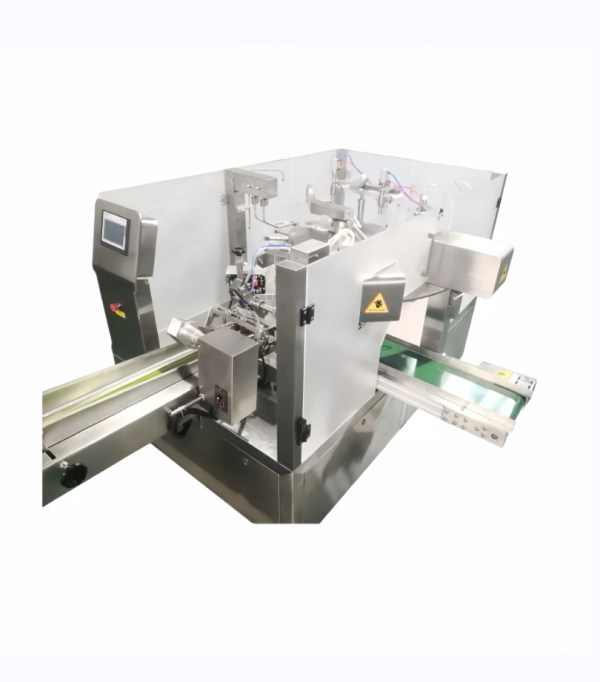

What is a Zipper Pouch Packing Machine?

A zipper pouch packing machine is an automated system designed to fill and seal zipper pouches, typically used for packaging food, beverages, cosmetics, and other consumer products. These machines are capable of creating the pouch, filling it with the desired product, sealing it, and adding a zip closure for easy access and reusability. The zipper closure is one of the key features that sets zipper pouches apart from traditional packaging options, offering consumers the ability to reseal the package to maintain freshness.These machines offer an efficient, cost-effective, and highly customizable solution for a wide range of industries, ensuring that products are packaged quickly, securely, and in an appealing manner.

Advantages of Zipper Pouch Packaging

1.Convenience and ResealabilityOne of the main reasons zipper pouch packaging is so popular is its resealable feature. Consumers love the ability to open and close the package multiple times without the product spilling out. This is especially beneficial for food products like snacks, grains, or pet food, which require frequent access without losing freshness.

2.Product Freshness

Zipper pouches provide a tight seal, which helps protect the contents from moisture, air, and contaminants. This makes zipper pouch packaging an excellent option for preserving the shelf life of products, especially those that are sensitive to environmental factors.

3.Space-Efficient Design

Zipper pouches are lightweight and flexible, allowing them to take up less space than rigid packaging alternatives such as jars or boxes. This space-efficient design also contributes to lower transportation costs, as more pouches can be stacked and stored in less space.

4.Customizable Features

Zipper pouches come in various sizes, designs, and materials. Manufacturers can customize the pouches with attractive graphics, branding, and product information to enhance shelf appeal and attract consumers. This flexibility in design and printing makes zipper pouches an excellent packaging solution for branding and marketing purposes.

5.Eco-Friendly

Many zipper pouches are made from recyclable or biodegradable materials, making them an eco-friendly packaging option. With increasing consumer demand for sustainable products, manufacturers are increasingly opting for zipper pouches made from materials that can be recycled or are biodegradable.

How Does a Zipper Pouch Packing Machine Work?

A zipper pouch packing machine is designed to perform multiple functions in one streamlined process, improving efficiency and reducing labor costs. Here’s how the machine typically works:1.Feeding Material

The packaging material, usually in the form of a roll of flexible film, is fed into the machine. The film is typically printed with product branding, labels, and necessary information before being loaded onto the machine.

2.Pouch Formation

The machine forms the zipper pouch from the film, cutting and sealing the material to create the bottom and sides of the pouch. The zipper feature is also incorporated during this step, ensuring the closure is securely attached to the pouch.

3.Filling

Once the pouch is formed, the machine is ready to fill it with the desired product. Depending on the product being packaged, the machine can be equipped with various filling systems such as volumetric fillers, auger fillers (for powders), or liquid fillers (for liquids). The filling process is precise and ensures consistent quantities of product are dispensed into each pouch.

4.Sealing and Zipping

After the pouch is filled, the machine seals the top of the pouch using heat or pressure. The zipper mechanism is typically integrated into this step, ensuring that the closure is secure and functional.

5.Cutting and Ejection

Once sealed, the machine cuts the finished pouch from the rest of the film roll and ejects it into the collection bin. The pouches are now ready for inspection, packaging, and distribution.

Key Features to Look for in a Zipper Pouch Packing Machine

1.Speed and EfficiencyWhen choosing a zipper pouch packing machine, consider its production speed. High-quality machines can package hundreds or even thousands of pouches per hour, depending on the type of product and size of the pouches.

2.Versatility

A good machine should be versatile enough to handle different types of products, from food and beverages to non-food items like cosmetics or household products. Look for a machine that can be easily adjusted to accommodate different pouch sizes and materials.

3.Durability and Maintenance

A reliable zipper pouch packing machine should be built to last and require minimal maintenance. Ensure that the machine is made from high-quality materials and comes with a warranty and customer support for repairs.

4.Customizability

Some machines offer customization options, such as adjustable filling systems or the ability to add different types of zippers (e.g., sliders or press-to-close). This flexibility allows businesses to tailor the machine to their specific packaging needs.

Industries Using Zipper Pouch Packing Machines

Zipper pouch packing machines are used in a wide range of industries, including:●Food and Beverage: Packaging snacks, coffee, tea, spices, frozen foods, and beverages.

●Cosmetics and Personal Care: Packaging shampoos, lotions, face masks, and other personal care products.

●Pharmaceuticals: Packaging supplements, vitamins, and medications.

●Pet Products: Packaging pet food, treats, and other pet supplies.

Conclusion

The zipper pouch packing machine has become a critical tool in modern packaging, offering efficiency, cost savings, and convenience for businesses across various sectors. Its ability to create durable, secure, and resealable pouches makes it an ideal solution for packaging a wide range of products, particularly in the food and consumer goods industries.As demand for convenient, eco-friendly, and customizable packaging solutions continues to rise, the zipper pouch packing machine is poised to remain an integral part of the packaging industry, helping businesses meet consumer expectations while optimizing production processes.